Ss Lobe Pump

24000 INR/Piece

Minimum Order Quantity : 1 Pieces

Delivery Time : 7 Days

Voltage 415 Volt (v)

Usage Industrial

Speed 1440 RPM

Pressure Medium Pressure

Power Electric

Material Stainless Steel

Head Size Up to 50 Mtr

Frequency 50 Hertz (HZ)

Flow Rate 20000 LPH

Color Blue

Supply Ability 10 Per Month

About this product

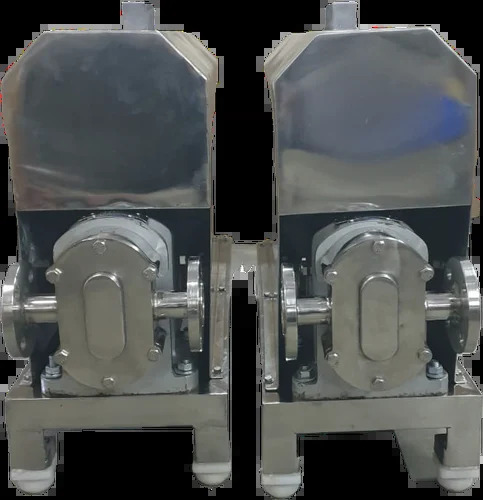

Horizontal Rotary Lobe Pump

62500 INR/Piece

Minimum Order Quantity : 1 Pieces

Delivery Time : 7 Days

Voltage 220 Volt (v)

Usage Industrial

Speed 100 to 720 RPM

Pressure Medium Pressure

Material Stainless Steel

Frequency 50 Hertz (HZ)

Flow Rate 5000 LPH

Capacity 75 m3/hr

Supply Ability 10 Per Month

About this product

Highly Viscous Suction Lobe Pump

28500 INR/Piece

Minimum Order Quantity : 1 Pieces

Delivery Time : 7 Days

Voltage 415 Volt (v)

Usage Industrial

Speed 1440 RPM

Pressure Medium Pressure

Power Electric

Material Stainless Steel

Head Size Up to 40 Mtr

Frequency 50 Hertz (HZ)

Flow Rate 8000 LPH

Color Blue

Supply Ability 10 Per Month

About this product

Rotary Lobe Pumps in mumbai

45000 INR/Piece

Minimum Order Quantity : 1 Pieces

Delivery Time : 7 Days

Voltage 415 Volt (v)

Usage Industrial

Speed 1440 RPM

Pressure Medium Pressure

Power Electric

Material Stainless Steel

Frequency 50 Hertz (HZ)

Flow Rate 25000 LPH

Color Blue

Supply Ability 10 Per Month

About this product

Ointment Transfer Pump

38200 INR/Piece

Minimum Order Quantity : 1 Pieces

Delivery Time : 7 Days

Voltage 415 Volt (v)

Usage Industrial

Speed 1440 RPM

Pressure Medium Pressure

Power Electric

Material Stainless Steel

Frequency 50 Hertz (HZ)

Flow Rate 5000 LPH

Supply Ability 10 Per Month

About this product

SS 316 Lobe Pump for Food and Pharma Applications

42800 INR/Piece

Minimum Order Quantity : 1 Pieces

Delivery Time : 7 Days

Voltage 415 Volt (v)

Usage Industrial

Speed 100 To 720 RPM

Pressure Medium Pressure

Power Electric

Material Stainless Steel

Frequency 50 Hertz (HZ)

Flow Rate 25000 LPH

Color Blue

Capacity 100 m3/hr

Supply Ability 10 Per Month

About this product

Rotary Lobe Pumps For Chemical Industry

38200 INR/Piece

Minimum Order Quantity : 1 Pieces

Delivery Time : 7 Days

Voltage 415 Volt (v)

Usage Industrial

Speed 1440 RPM

Pressure Medium Pressure

Power Electric

Material Stainless Steel

Frequency 50 Hertz (HZ)

Flow Rate 5000 LPH

Supply Ability 10 Per Month

About this product

Tomato Paste Transfer Pumps

25000 INR/Piece

Minimum Order Quantity : 1 Pieces

Delivery Time : 7 Days

Voltage 415 Volt (v)

Usage Industrial

Speed 1440 RPM

Pressure Medium Pressure

Power Electric

Material Stainless Steel

Frequency 50 Hertz (HZ)

Flow Rate 5000 LPH

Supply Ability 10 Per Month

About this product

Cosmetic Cream Transfer Pump

54000 INR/Piece

Minimum Order Quantity : 1 Pieces

Delivery Time : 7 Days

Voltage 220 Volt (v)

Usage Industrial

Speed 1440 RPM

Pressure Medium Pressure

Power Electric

Material Stainless Steel

Frequency 50 Hertz (HZ)

Flow Rate 10000 LPH

Supply Ability 10 Per Month

About this product

Three Phase Rotary Lobe Pump

22000 INR/Piece

Minimum Order Quantity : 1 Pieces

Delivery Time : 7 Days

Voltage 220 Volt (v)

Usage Industrial

Speed 1440 RPM

Pressure Medium Pressure

Power Electric

Material Stainless Steel

Head Size 50 Mtr

Frequency 50 Hertz (HZ)

Flow Rate 40 LPM

Supply Ability 10 Per Month

About this product

Shampoo Transfer Pump

42500 INR/Piece

Minimum Order Quantity : 1 Pieces

Delivery Time : 7 Days

Voltage 220 Volt (v)

Usage Industrial

Speed 1440 RPM

Pressure Medium Pressure

Power Electric

Material Stainless Steel

Frequency 50 Hertz (HZ)

Flow Rate 25000 LPH

Supply Ability 10 Per Month

About this product

Lobe Pump

Minimum Order Quantity : 1 Units

Delivery Time : 3-4 Days

Usage Industrial

Size Different Available

Product Type Lobe Pump

Pressure High Pressure

Material Metal

Supply Ability 10 Per Month

Payment Terms Cash in Advance (CID)

Main Domestic Market All India

About this product

FAQs of Lobe Pump:

Q: What material is the Lobe Pump made of?

A: The Lobe Pump is made of high quality metal.Q: What is the pressure rating of the Lobe Pump?

A: The Lobe Pump is designed for high pressure applications.Q: What are the available sizes of the Lobe Pump?

A: The Lobe Pump is available in different sizes to meet your specific needs.Q: Is the Lobe Pump easy to install and maintain?

A: Yes, the Lobe Pump is easy to install and maintain.Q: Is the Lobe Pump suitable for a variety of liquids?

A: Yes, the Lobe Pump is suitable for a variety of liquids, including viscous liquids.Explore Additional Categories

Contact Us

Our Products

Our Products